Turbine Generator Testing & Inspection Services

Reliable Turbine Services, LLC is a premier OEM generator repair services provider, powered by Fuji Electric, a world leader in turbine/generator manufacturing. This relationship brings a wealth of technical and engineering experience to RTS. This enables our personnel to deliver top-quality turbine generator inspection services through our GATE 1-2-3 program. Our team also provides 24/7 generator emergent services for generator outages that happen at your facility across the nation.

The GATE program is composed of individualized tests allowing customers the choice of either a test or an inspection package of services tailored to their specific needs. The GATE offerings are designed to meet the needs of each generator ensuring our customers have confidence that no potential issue will go undetected. Our GATE testing programs grant our customers peace of mind knowing your turbine generator inspection will produce power reliably once returned to service. Our OEM generator repair services trained specialists and engineers have the prowess to test, repair, and maintain generators of all sizes and types.

To find out more about RTS’ OEM Generator Repair Services download our Line Card here.

Click below to find out more.

Siemens

Elliott

Alstom

Mitsubishi

Hitachi

Murray, Terry, Coppus

Allis Chalmers

Have A Question?

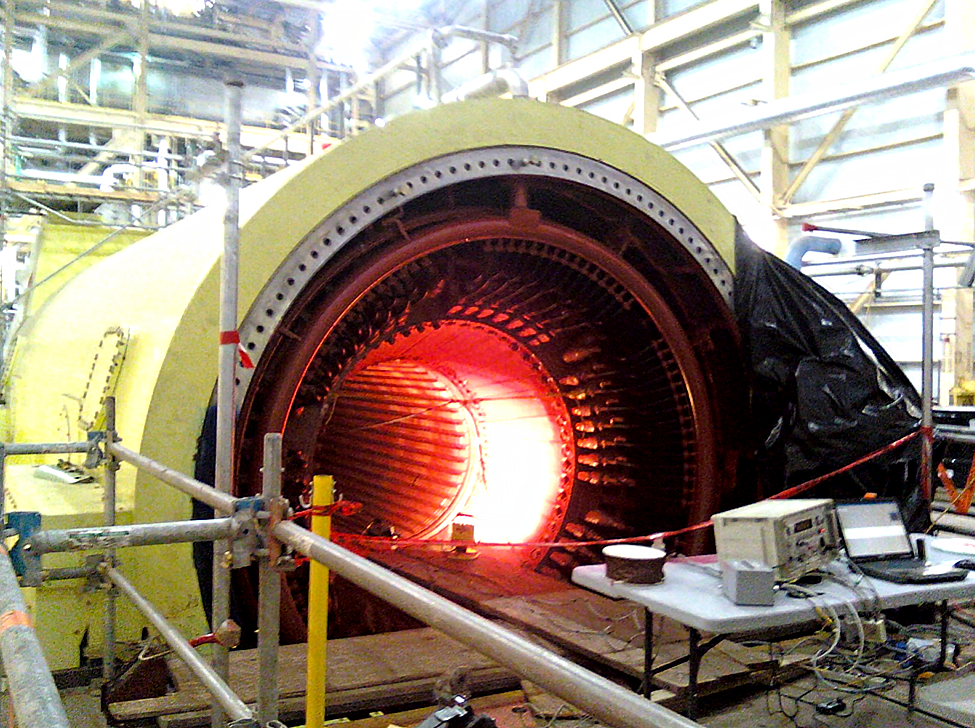

Minor inspection with generator rotor in place

Major inspection (rotor out) with limited testing

Major inspection with extensive testing

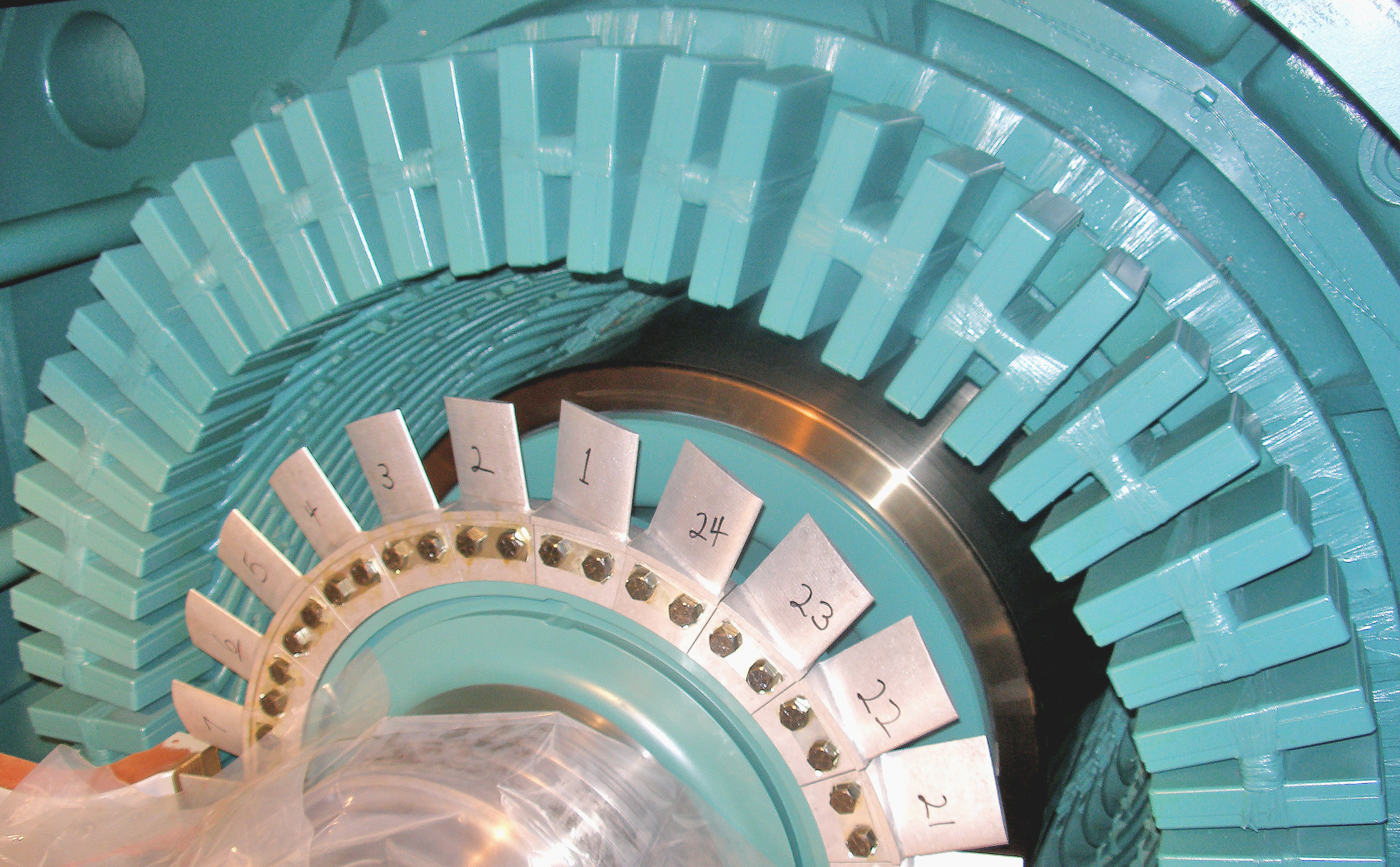

Rotor Services

Brushless exciter test, inspection and complete overhaul

Field ground detector troubleshooting for both RF and Optical systems

Retaining Ring inspection, removal & replacement

Non-destructive testing (NDT) of retaining rings

Collector ring repair, replace, and machining

Complete rotor rewind

Post-rewind high speed balancing

Radial hydrogen seal replacement

Wedge replacement

Repair turn shorts

Terminal Stud repair & replacement

Endwind blocking

Creepage blocks

Rotor Testing

Insulation resistance & polarization index (“megger & P.I.”)

DC resistance testing

AC impedance test

Pole balance test

Recurring Surge Oscillography (RSO) test for shorted turns

Hydrogen seal pressure test for leaks

Borescope visual inspection

Additional Capabilities

Consultant services

Root cause analysis

Silver plating (electro-plating) bus work mating surfaces

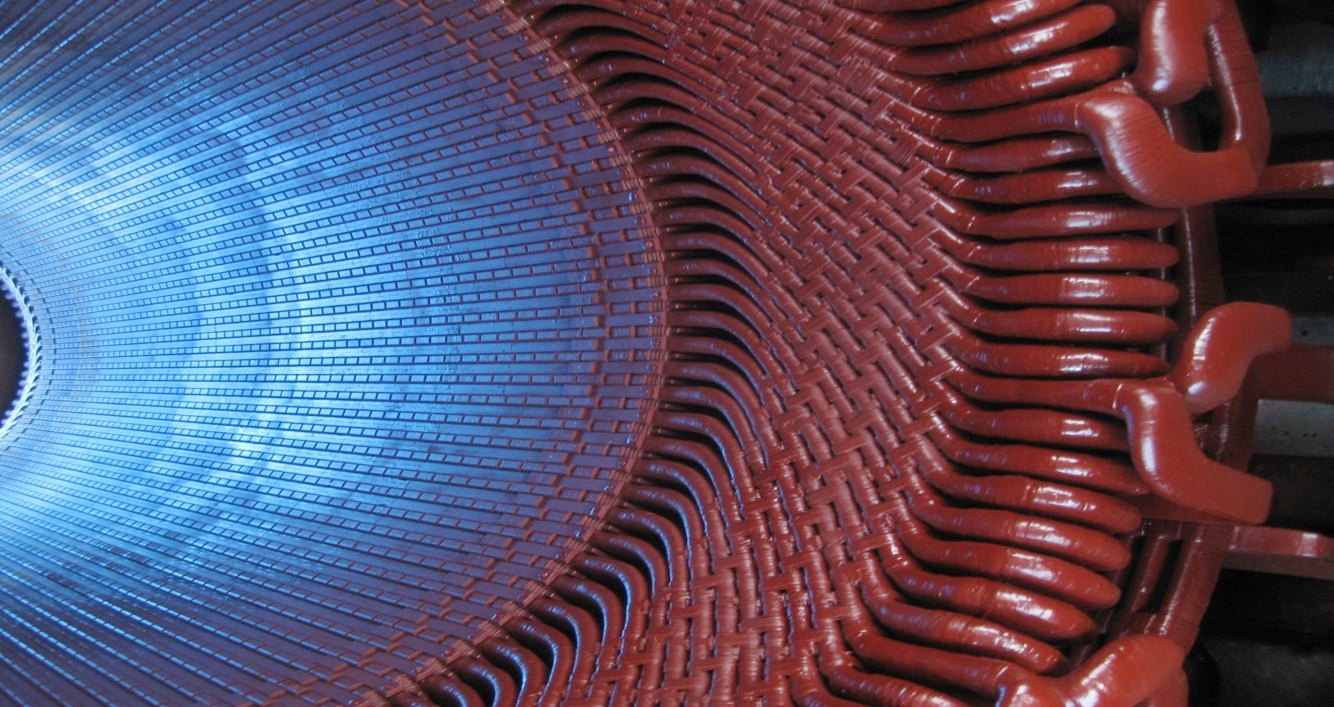

Stator Services

End winding resonance detection and repairs “bump test”

Connection ring / parallel ring re-blocking & re-tying

End winding, re-blocking, & re-tying based on bump test & visual inspection results

End winding stiffening treatment

Corona and partial discharge activity abatement

Stator re-wedging

Flux probe installation

Dry ice “CO2” blasting excessively contaminated stators

High voltage bushing replacement

Temporary High voltage bushing & terminal plate leak repairs (“damming”)

Replacement of stand-off insulators

Stator core iron repairs

Stator Testing

Insulation resistance & polarization index (“megger & P.I.”)

DC Leakage test and Hi Pot

ELCID testing for core faults

Digital wedge mapping

Ripple / PSDS spring depth gage testing for wedge tightness

DC resistance testing of each phase

Bump test / modal analysis of end windings & connection rings

Corona camera

Doble / Tan-Delta / Power Factor testing

Thermographic detection of high resistance connections

Westinghouse / MHI inner-cooled unit testing including:

Transposition Testing

Tube to tube resistance test

Tube to copper resistance test

Core through bolt & building bolt torque checks & re-tightening

Megger of through bolts

Parallel ring flow testing